♦ Robotic Milking Systems

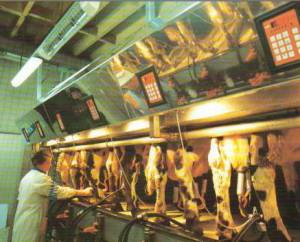

♦ Conventional Milking Systems

♦ Goat and Sheep Milking Equipments

♦ Claw pieces

♦ Milk Meters

♦ Milk Receivers

♦ Vacuum Equipment

♦ Pulsation Systems

♦ In Parlour Feeding Systems

♦ Out of Parlour Feeding Systems

♦ Mobile Milkers and Bucket Systems

♦ Milk Cooling Systems

♦ Washing Systems |

|

|

|

|

|

|

|

Benefits of a Multi Sided System.

♦ excellent visibility for good observation

♦ faster throughput.

♦

reduction in lost time by more, shorter rows of cows.

♦ working comfort

improved by increased pit area.

♦ milking rate increased |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

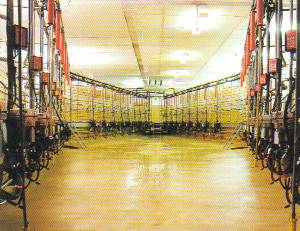

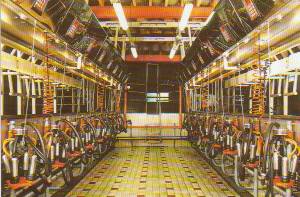

Benefits of a Parallel System.

♦ speed.

♦ milking quality.

♦ ease of cluster attachment.

♦ Reduced movement for the operator during milking.

Side by side positioning of the animals, at right angles to the

pit deceases the pit length thus reducing the distance operator has to walk |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parallel stalls with rapid exit

The rapid exit parlour is characterized by the modular stalls which can go from four to fifty places. Access to the milking area is controlled by Western gates. Exit from the parlour is faster thanks to the complete evacuation of one side by pneumatically powered lifting yokes.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|